Key Features

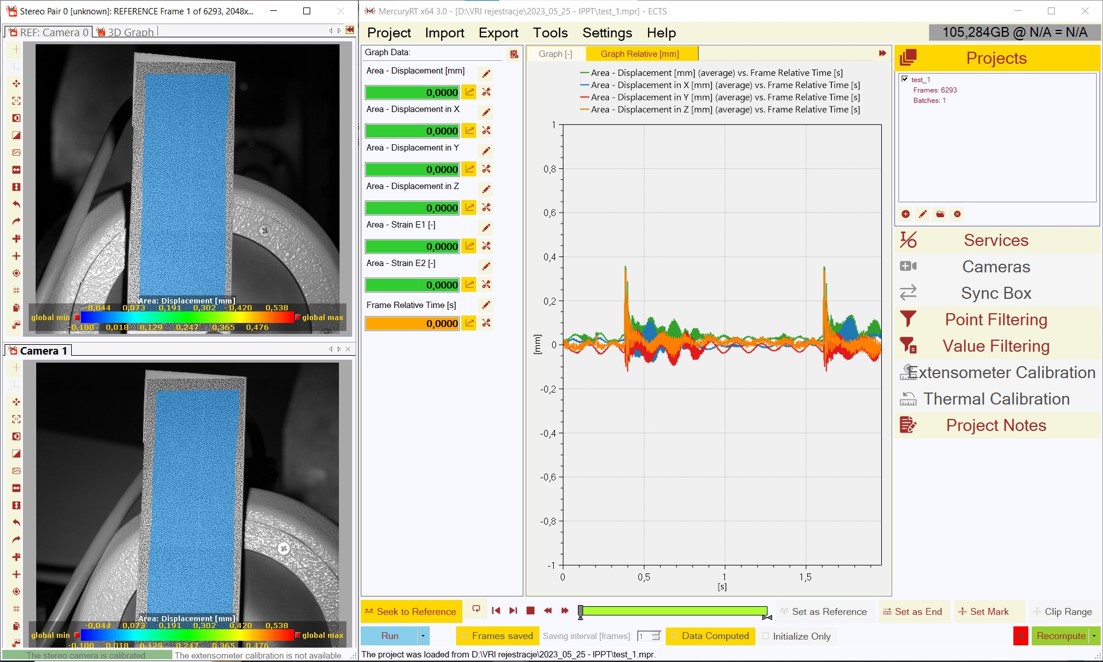

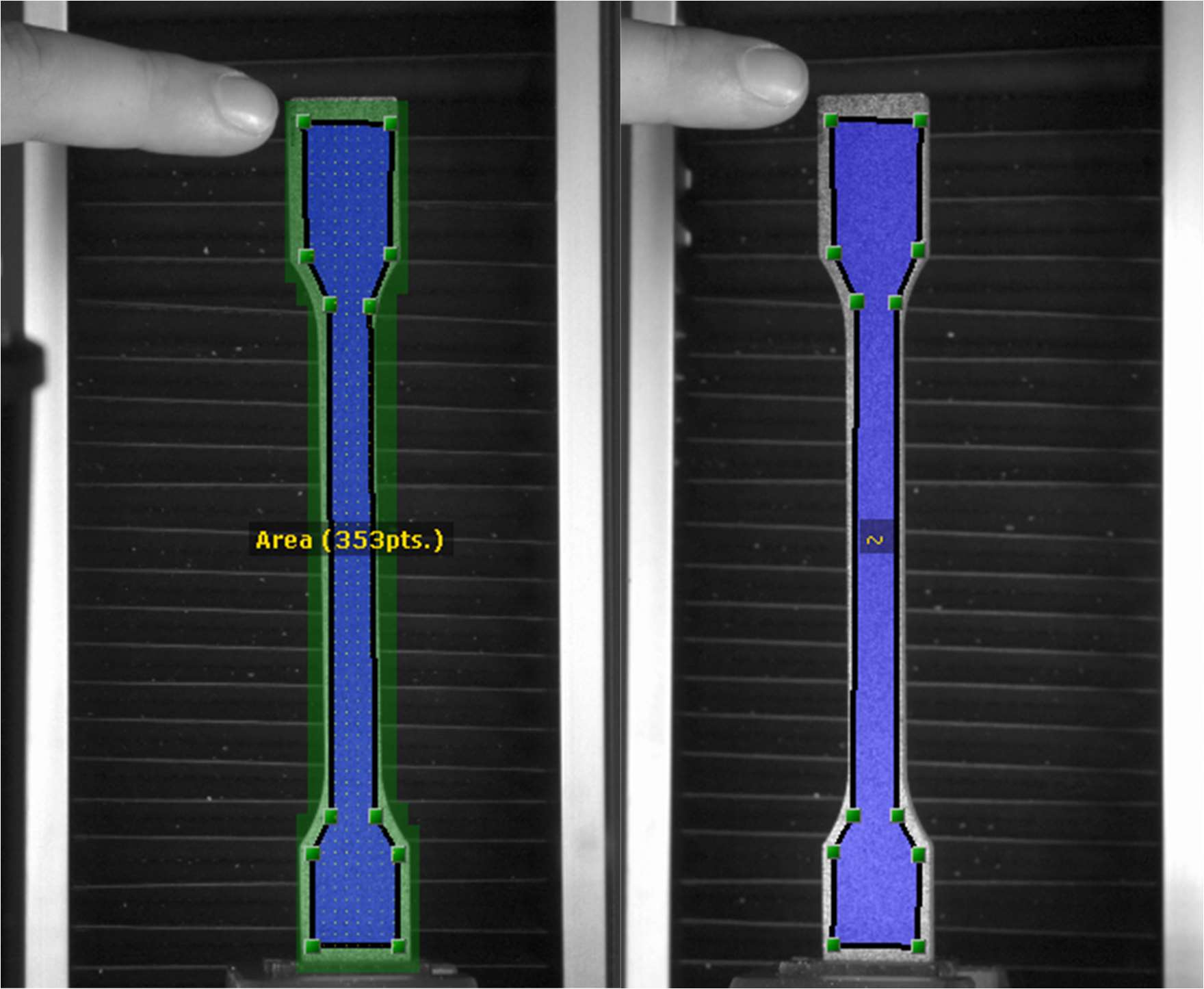

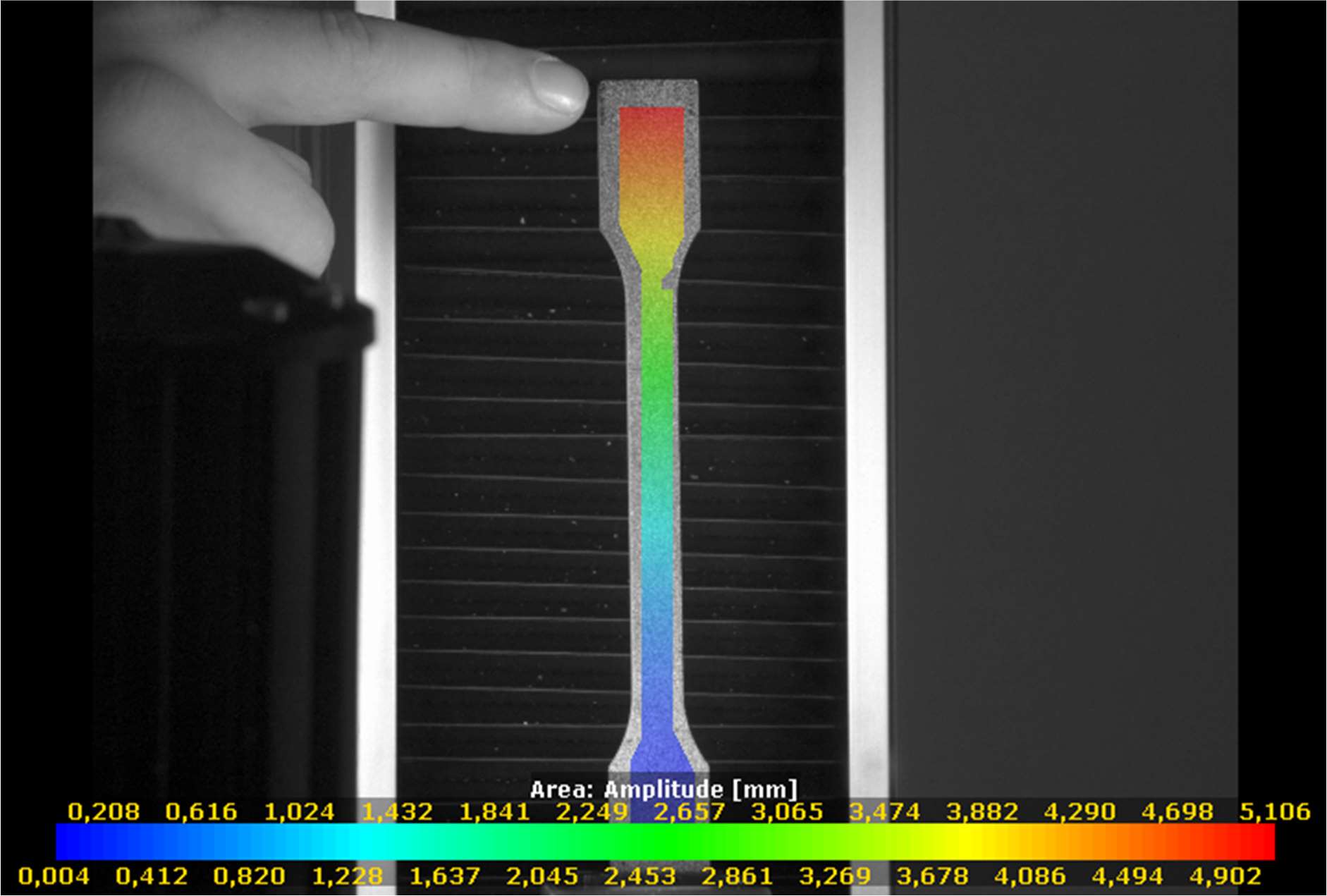

❖ Full-field measurement: System allows to measure strain, displacement ans position variables. mearovides detailed insight into data within the frequency domain, making it ideal for examining natural frequencies and operational deflection shapes.

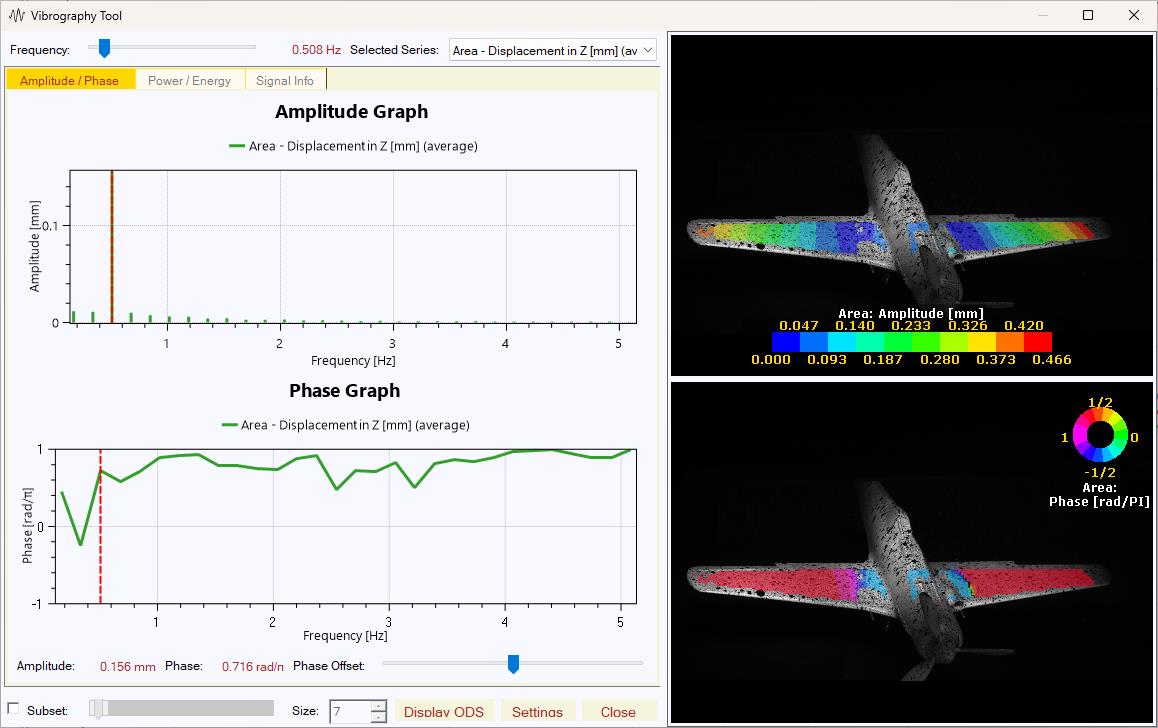

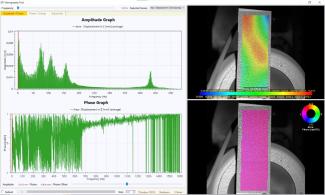

❖ Operational Deflection Shapes (ODS): Analyze full-field ODS at frequencies ranging from low to high. Visualize the ODS animations in a 3D environment to better understand dynamic responses.

❖ Natural Frequency Identification: Accurately detect natural frequencies and their associated ODS, enabling precise diagnostics of structural vibrations.

❖ Advanced FFT Analysis: Perform detailed analysis with advanced Fast Fourier Transform (FFT) capabilities, including octave analysis, subset analysis, and multiple methods for extracting natural frequencies. Choose from a variety of window functions for tailored analysis.

❖ Cost-Efficient and User-Friendly: Enjoy a powerful yet cost-effective system designed for seamless setup and operation, offering advanced functionalities with a focus on convenience and efficiency.

Use cases Operational Deflection Shapes (ODS)

Automotive Industry:

Door slam testing to analyze structural response.

Evaluating vibrations in exhaust systems and engine components.

Assessing suspension and chassis dynamics.

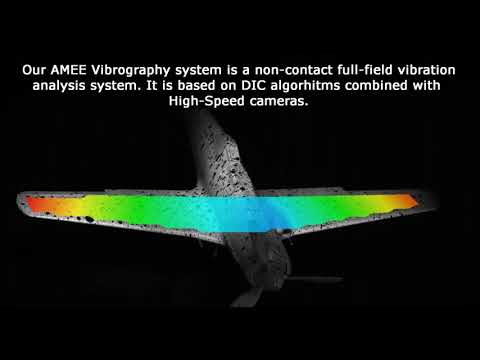

Aerospace Industry:

Studying vibrations in aircraft wings, fuselage, and joints.

Testing turbine engines and rotating components.

Machinery Diagnostics:

Monitoring vibrations in rotating machinery such as motors, turbines, and pumps.

Identifying imbalances, misalignments, and bearing faults.

Structural Health Monitoring:

Analyzing deflection and stress in buildings, bridges, and other structures.

Identifying weaknesses or damage after seismic or dynamic events.

Product Development and Quality Control:

Testing prototypes to improve designs.

Ensuring product reliability by identifying resonance and fatigue points.

Applications