DIC

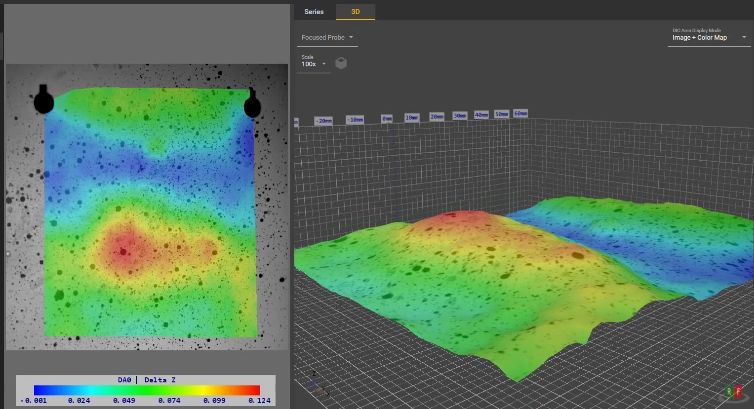

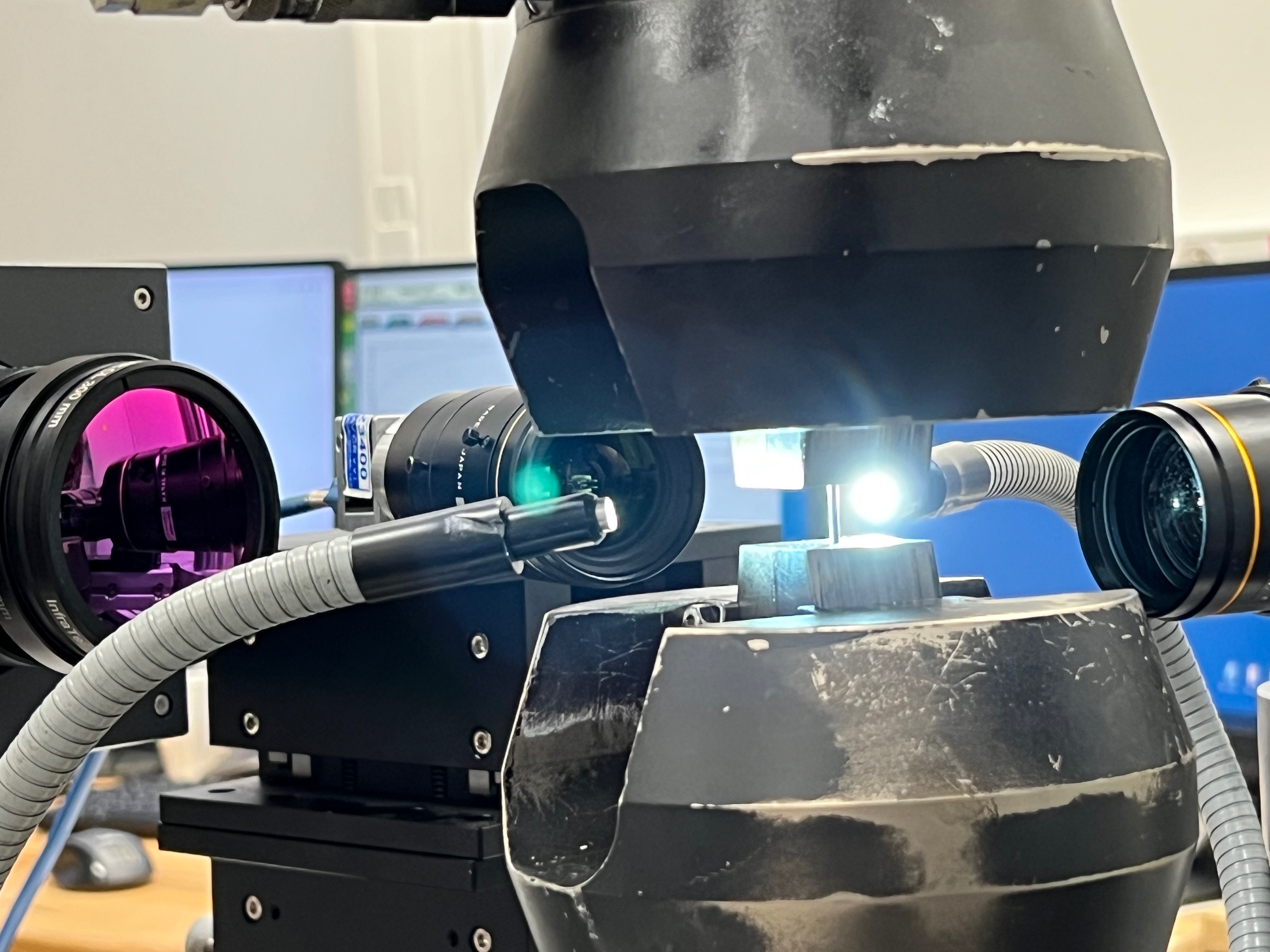

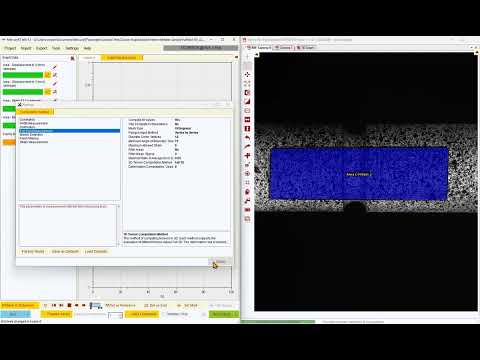

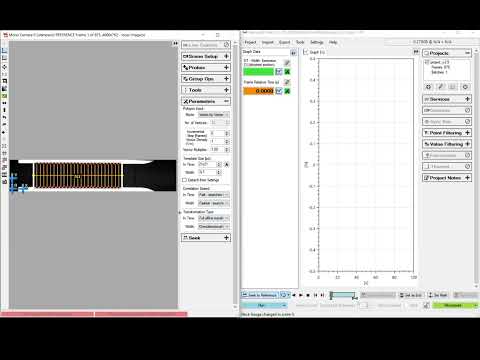

Mercury RT is a software technology that uses Digital Image Correlation (DIC) technique to perform 2D/3D full-field with a non-contact optical technique to measure contour, deformation, vibration and strain on almost any material. It provides on-line data acquisition as well as data processing.

MERCURY RT Core Features:

❖ Material Testing: Evaluate material properties with high precision.

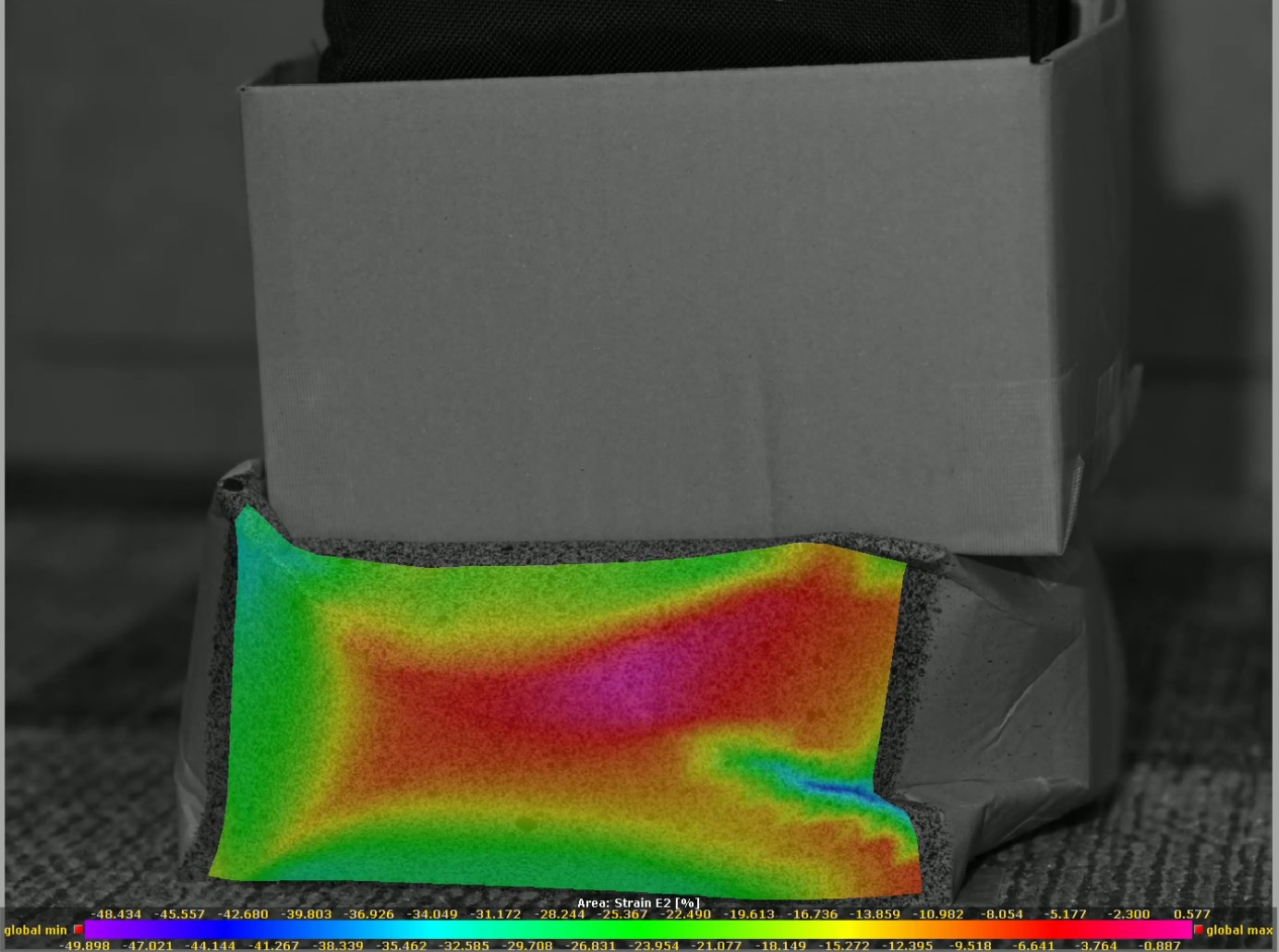

❖ Component Testing: Analyze the behavior of various components under different conditions.

❖ Finite Element Analysis (FEA) Validation: Validate FEA results with real-world deformation data.

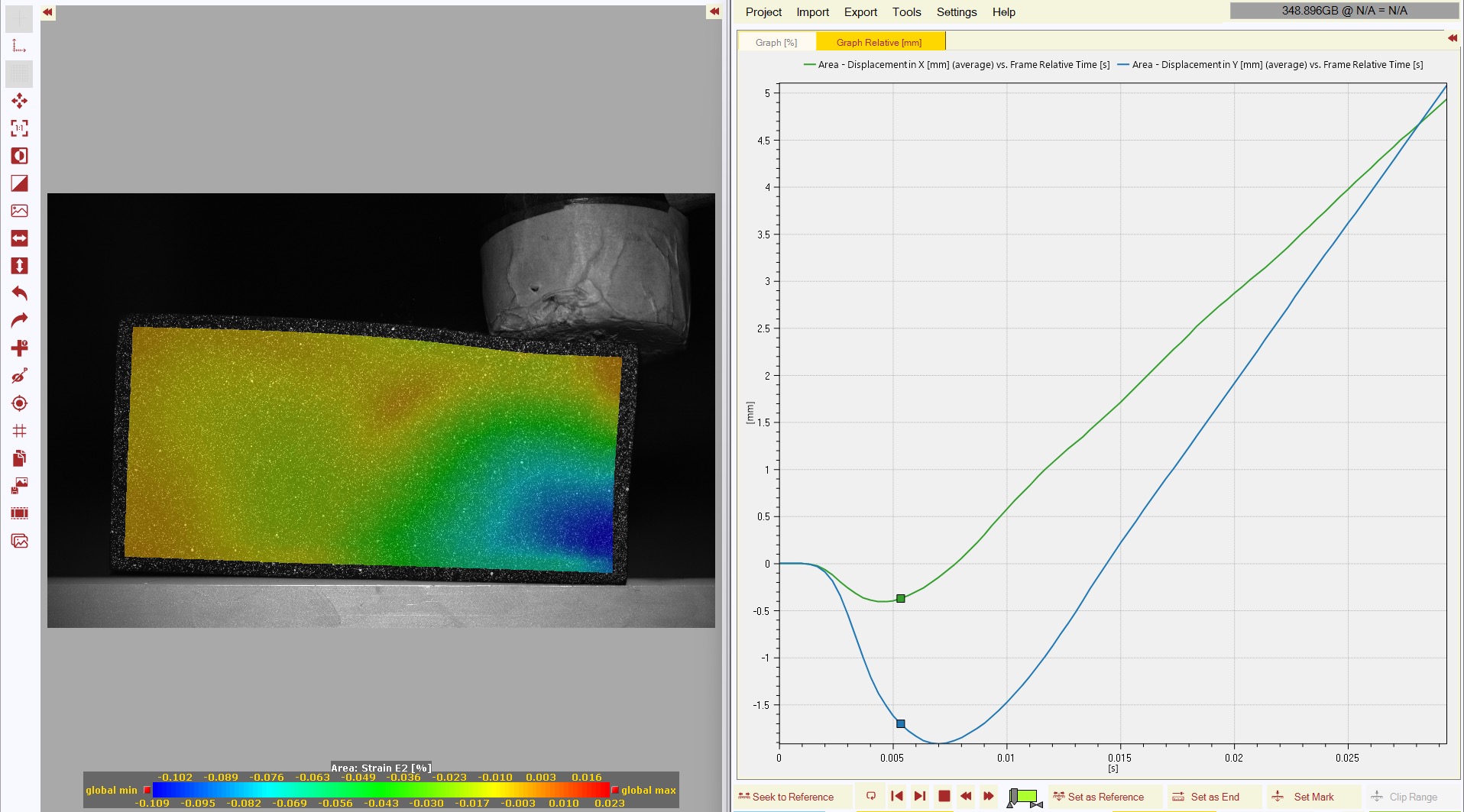

❖ Vibrography: Study vibrations and oscillations in structures.

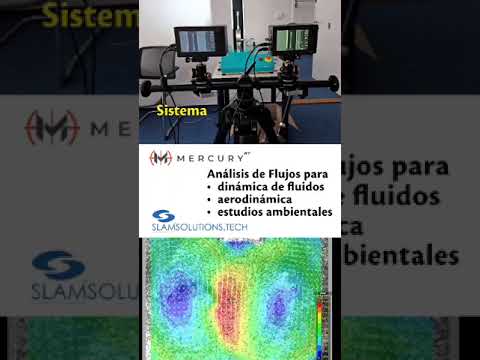

❖ Flow/Motion Field Measurement: Understand and visualize the flow or motion fields in your experiments.

❖ Test Rig Control: Have control over your test rig for comprehensive experiments

❖ Support for high-speed cameras to capture fast events with precision.

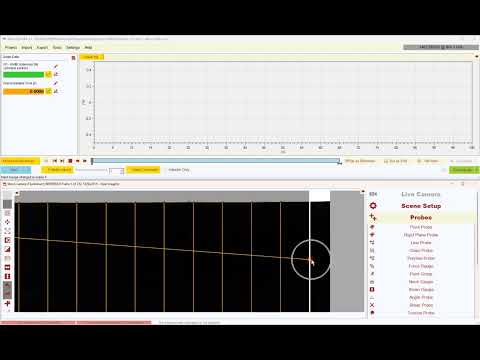

Probes

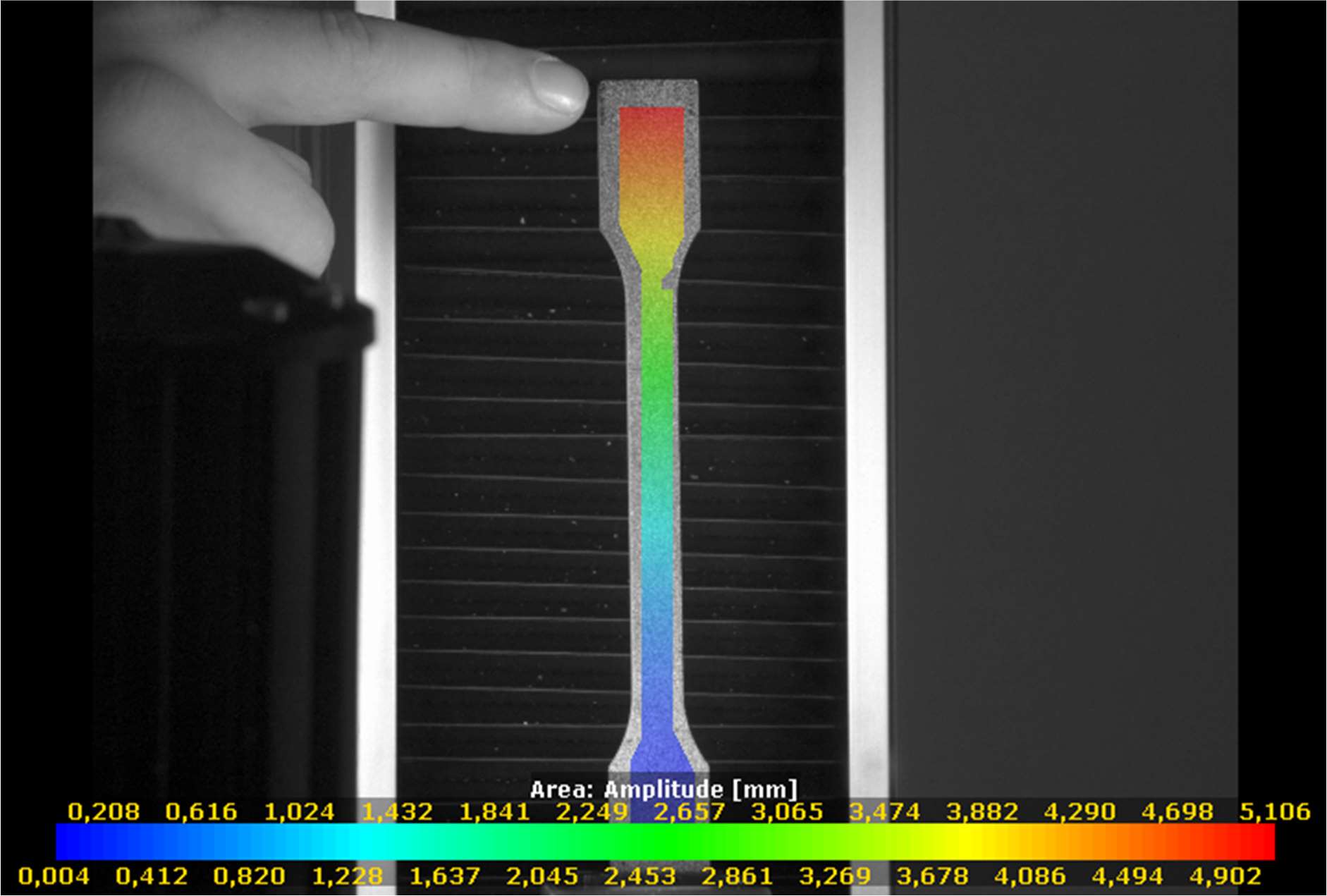

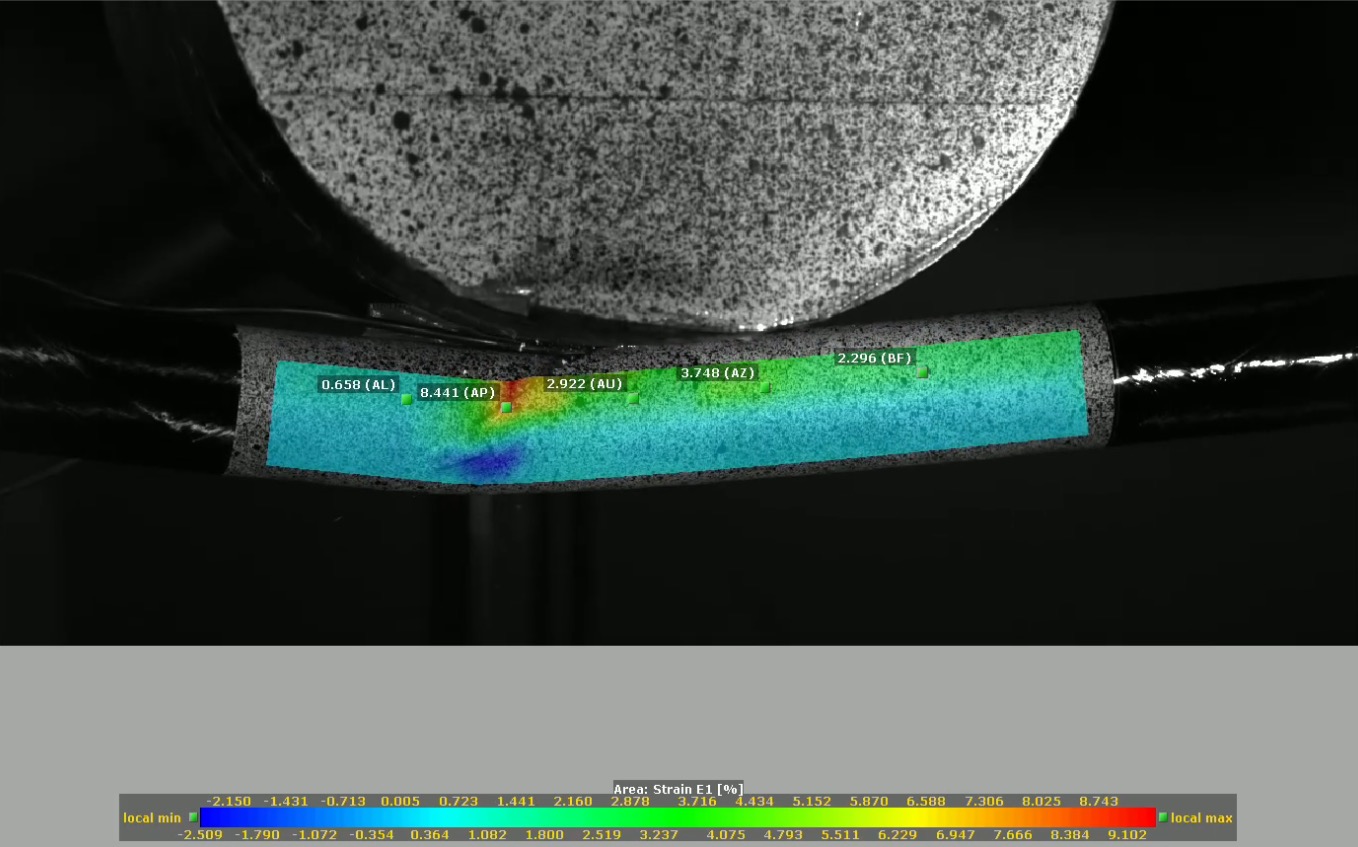

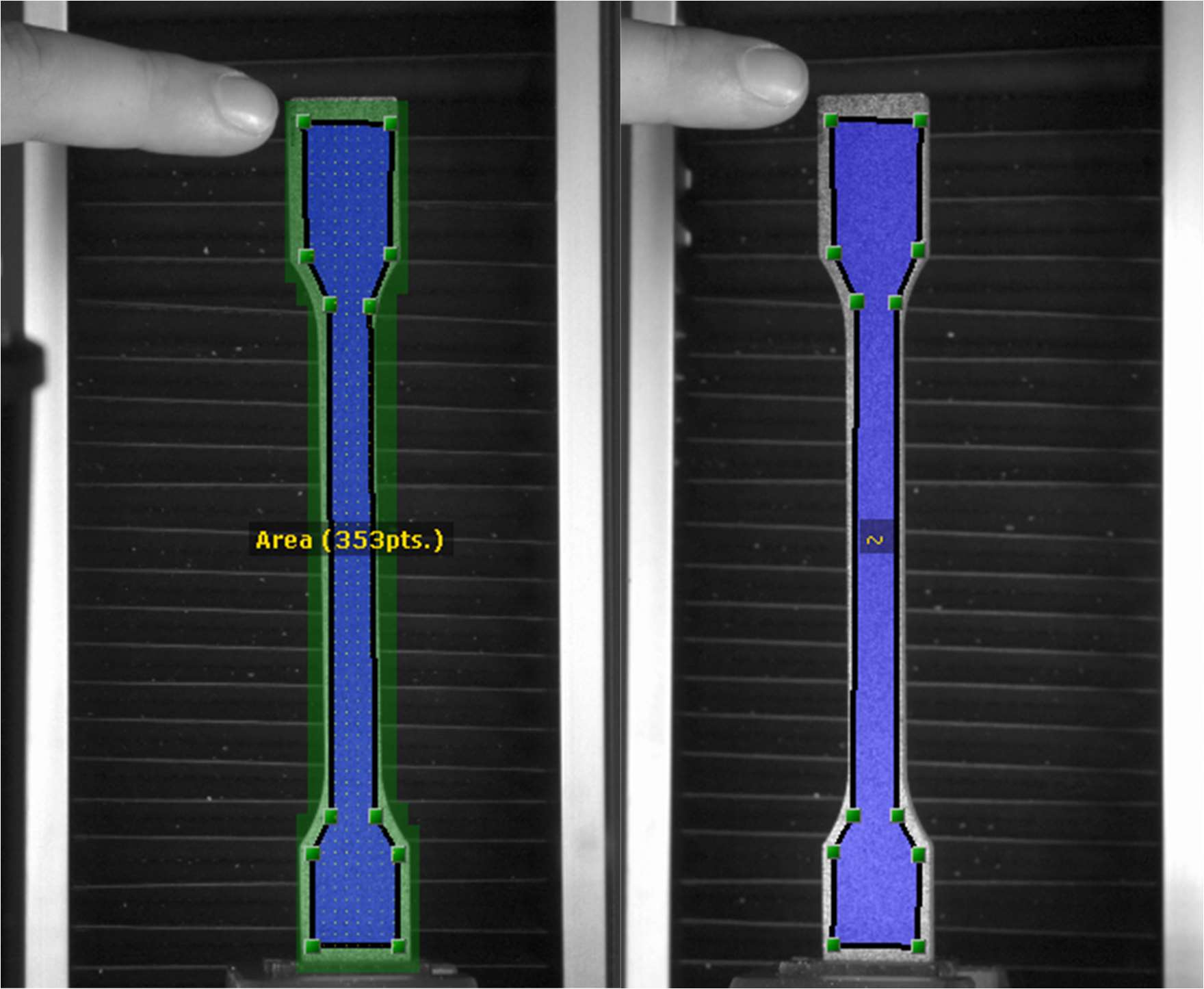

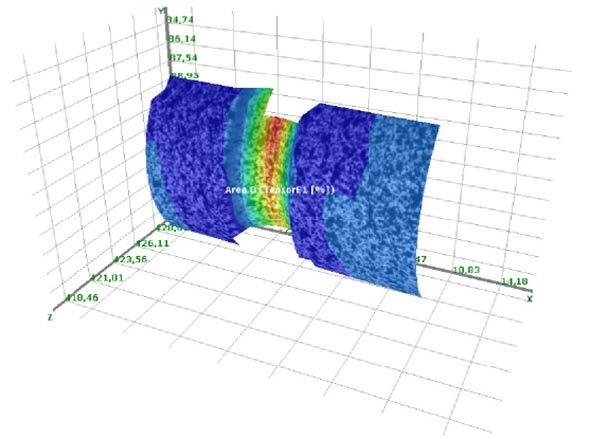

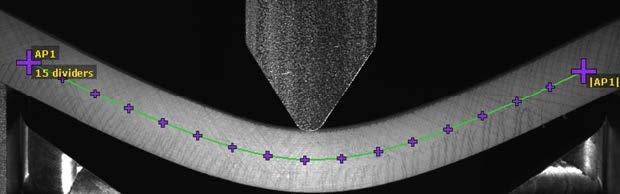

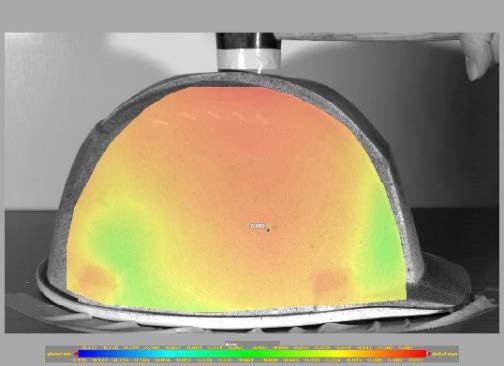

Tracking probes in Mercury RT® are essential tools for measuring and analyzing the behavior of materials using Digital Image Correlation (DIC) under various conditions. These probes allow users to track specific points, lines, or areas of interest, capturing detailed data on displacements, deformations, and other critical parameters. Mercury RT® offers a variety of DIC tracking probes, including Point Probe, Line Probe, Chain Probe, Area Probe, and specialized probes like Neck Gauge, Torsion Probe, and Crack Probe that are available only in Mono Mode.

What can you measure: Length and Extension; Width measurement; Tensile Testing; Angle measurement; Position and Displacement; Twist; Strains and deformations; Strain rate; Stress

Gallery